- Production tool high point nc how to#

- Production tool high point nc manual#

- Production tool high point nc full#

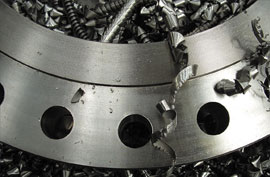

The machinist programs instructions into the CNC machine to determine the cutting path, cutting speed, and feed rate.Īlthough workers may produce large quantities of one part, precision machinists often produce small batches or single items. CNC machines control the cutting tool speed and do all necessary cuts to create a part.

Many machinists must be able to use both manual and CNC machinery. Machinists use lathes, milling machines, grinders, and other machine tools to produce precision metal parts. Smooth and polish the surfaces of tools and dies.Test completed tools and dies to ensure that they meet specifications.File, grind, and adjust parts so that they fit together.Set up, operate, and disassemble conventional, manual, and CNC machine tools.Compute and verify dimensions, sizes, shapes, and tolerances of workpieces.

Read detailed drawings or files-such as blueprints, sketches, specifications, and those for CAD and CAM-to make tools, molds, and dies. Tool and die makers typically do the following: Verify that completed products meet requirements. Turn, mill, drill, shape, and grind machine parts to specifications. Align, secure, and adjust cutting tools and workpieces. Set up, operate, and disassemble manual, automatic, and computer numerically controlled (CNC) machine tools. Read detailed drawings or files, such as blueprints, sketches, and those for computer-aided design (CAD) and computer-aided manufacturing (CAM). Machinists and tool and die makers set up and operate a variety of computer-controlled and mechanically controlled equipment to produce precision metal parts, instruments, and tools. What Machinists and Tool and Die Makers Do About this section Learn more about machinists and tool and die makers by visiting additional resources, including O*NET, a source on key characteristics of workers and occupations. More Information, Including Links to O*NET Similar OccupationsĬompare the job duties, education, job growth, and pay of machinists and tool and die makers with similar occupations. Most of those openings are expected to result from the need to replace workers who transfer to different occupations or exit the labor force, such as to retire.Įxplore resources for employment and wages by state and area for machinists and tool and die makers. Overall employment of machinists and tool and die makers is projected to show little or no change from 2021 to 2031.ĭespite limited employment growth, about 44,100 openings for machinists and tool and die makers are projected each year, on average, over the decade. The median annual wage for tool and die makers was $57,000 in May 2021. The median annual wage for machinists was $47,730 in May 2021. Some learn through training or apprenticeship programs, vocational schools, or community and technical colleges. Machinists and tool and die makers typically are trained on the job.

Read detailed drawings or files-such as blueprints, sketches, specifications, and those for CAD and CAM-to make tools, molds, and dies. Tool and die makers typically do the following: Verify that completed products meet requirements. Turn, mill, drill, shape, and grind machine parts to specifications. Align, secure, and adjust cutting tools and workpieces. Set up, operate, and disassemble manual, automatic, and computer numerically controlled (CNC) machine tools. Read detailed drawings or files, such as blueprints, sketches, and those for computer-aided design (CAD) and computer-aided manufacturing (CAM). Machinists and tool and die makers set up and operate a variety of computer-controlled and mechanically controlled equipment to produce precision metal parts, instruments, and tools. What Machinists and Tool and Die Makers Do About this section Learn more about machinists and tool and die makers by visiting additional resources, including O*NET, a source on key characteristics of workers and occupations. More Information, Including Links to O*NET Similar OccupationsĬompare the job duties, education, job growth, and pay of machinists and tool and die makers with similar occupations. Most of those openings are expected to result from the need to replace workers who transfer to different occupations or exit the labor force, such as to retire.Įxplore resources for employment and wages by state and area for machinists and tool and die makers. Overall employment of machinists and tool and die makers is projected to show little or no change from 2021 to 2031.ĭespite limited employment growth, about 44,100 openings for machinists and tool and die makers are projected each year, on average, over the decade. The median annual wage for tool and die makers was $57,000 in May 2021. The median annual wage for machinists was $47,730 in May 2021. Some learn through training or apprenticeship programs, vocational schools, or community and technical colleges. Machinists and tool and die makers typically are trained on the job. How to Become a Machinist or Tool and Die MakerĪlthough machinists typically need a high school diploma to enter the occupation, tool and die makers also may need to complete postsecondary courses. However, working overtime, as well as nights and weekends, may be common.

Many work full time during regular business hours. Machinists and tool and die makers work in machine shops and factories. Machinists and tool and die makers set up and operate equipment to produce precision metal parts, instruments, and tools. What Machinists and Tool and Die Makers Do Quick Facts: Machinists and Tool and Die Makers Please enable javascript to play this video.

0 kommentar(er)

0 kommentar(er)